Capabilities

Innovative Precision Manufacturing Services at WPA Works LLC

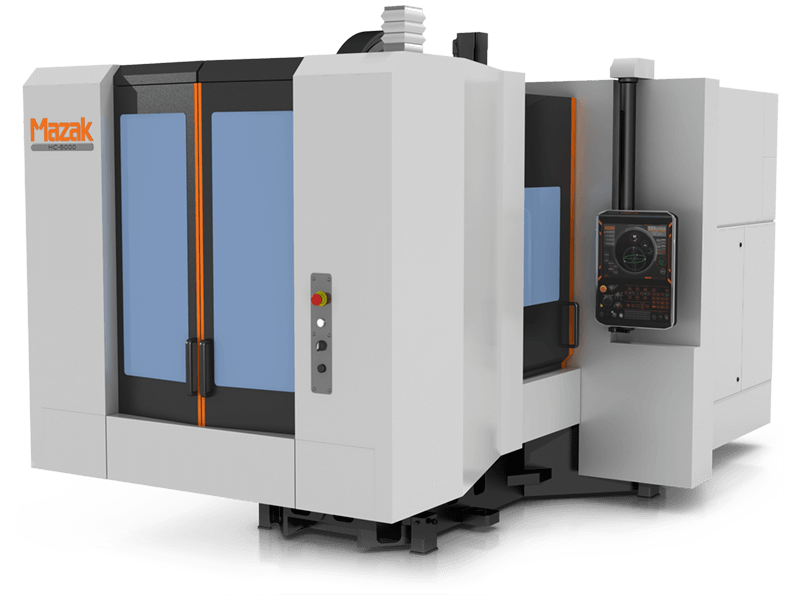

At WPA Works LLC, our precision manufacturing services leverage advanced manufacturing technologies and equipment from industry-leading producers to create high-quality, precision-engineered products.

Our expertise in precision manufacturing services spans a wide range of industries, including Aerospace, Space, Defense, Energy, Medical, Biotech, and more. We deliver products that meet the stringent requirements of our diverse clientele, showcasing the breadth of our precision manufacturing capabilities.

Explore the vast array of products we can manufacture, all underscored by our unwavering commitment to innovation, quality, and precision.

Details on WPA Works LLC Equipment List, reflecting our precision manufacturing services, are available here.

5-Axis Machining

Our 5-Axis Machining capabilities redefine precision, enabling the machining of complex parts from virtually any angle in a single setup. This advanced technology ensures unparalleled accuracy and surface finish, meeting the highest standards for intricate designs and tight tolerances.

4-Axis Machining

Our 4-Axis Machining services unlock new dimensions of precision and efficiency, allowing for complex parts to be machined on four sides in a single setup. This capability reduces handling time and increases accuracy, making it ideal for complex geometries that require precise angles and intricate cuts.

3-Axis Machining

The foundation of our milling operations, 3-Axis Machining, provides a robust solution for a wide array of machining needs, from simple cuts to more complex shapes. By moving the workpiece in three dimensions, we ensure high-quality surface finishes and consistent precision across every project, making it a versatile choice for all types of production.

Dual Spindle Turning Centers

Dual Spindle Turning Centers at our facility enable simultaneous machining, drastically reducing cycle times while maintaining high precision and surface finish. This advanced turning capability is designed to meet specific customer needs with accuracy.

Ultra Precision

Swiss Machining at our company stands out for delivering ultra-precise components, especially for small parts with tight tolerances, thanks to our sophisticated technology. High-volume production benefits from the efficiency and reliability of our Swiss Machining processes.

Laser Marking

We provide permanent, high-resolution marking for product identification, branding, and traceability, ensuring clarity and durability.

Customizable Marking Solutions

Our laser marking technology offers customizable solutions to meet unique client requirements, enabling a wide range of designs, from intricate logos to precise barcodes and serial numbers, adaptable across various materials and surfaces.

for Intricate Machining

Wire EDM

This technology allows for the precise cutting of hard materials, ideal for creating intricate components with fine details and smooth finishes.

Medical and Biotech

Life Sciences

High Precission

Our expertise in Complex Assemblies ensures that from the initial prototype to full-scale production, each project is handled with precision and care, tailored to customer specifications. This comprehensive service integrates high-quality parts into superior performance products.

at Every Step

Advanced Quality Control Equipment

Our commitment to quality is evident in our rigorous inspection and testing processes, ensuring that every product meets our high standards and those of our clients.

ISO 9001 and AS9100 Certified Processes

Our processes are certified to meet the highest international standards for quality management systems, reflecting our systematic approach to maintaining excellence.

Final Inspection and Testing

Before any product leaves our facility, it undergoes a final comprehensive inspection and testing phase to validate its quality and performance, guaranteeing customer satisfaction.

Advanced Processing Solutions through Precision Manufacturing Services

At the forefront of advanced component processing, WPA Works LLC’s precision manufacturing services offer an unmatched array of solutions designed to meet the exacting standards of industries reliant on precision and durability.

Our state-of-the-art facility is perfectly equipped to handle a broad spectrum of processing needs through our trusted vendor base, part of our commitment to precision manufacturing services.

This ensures that your components achieve the highest quality finish and performance characteristics required for demanding applications, epitomizing the essence of precision manufacturing services.

Internal Passivation Line

Our internal passivation line enhances the corrosion resistance of stainless steel components, ensuring longevity and reliability in critical applications. We certify to AMS 2700 Method II or Equivalent.

Anodizing

Gold Plating

Cadmium Plating

Known for its excellent corrosion resistance, cadmium plating service is used in aerospace and defense industries for critical components.

Black Oxide Plating

Offering mild corrosion resistance and minimal dimensional impact, black oxide plating is used for aesthetic, corrosion resistance, and functional purposes.

Zinc Plating

Chrome Plating

Known for its hardness and durability, chrome plating is used for wear resistance and aesthetic enhancement.

Copper Plating

Magnetic Particle Inspection

This non-destructive testing method ensures the integrity of components, detecting surface and slightly subsurface defects.

Radiography

Powder Coating

Heat Treating

We offer heat treating services to modify the physical and sometimes chemical properties of materials, optimizing performance and durability ia our trusted suppliers located locally in the heart of the Midwest

Gear Cutting

Gear Cutting capabilities of producing a variety of different gears and pulleys for a variety of applications, such as: spur, helical, internal, external, worm, bevel, sprocket and spline gears & shafts, as well as timing belt pulleys.

Why Choose Our Processing Services?

Partnering with us for your processing needs means benefiting from our comprehensive suite of services, each designed to enhance the performance and durability of your components.

Enhance the performance and longevity of your components with our advanced processing solutions. Contact us today to discover how we can support your project’s success.

Why WPA Works LLC?

Expert Team

Our team of skilled professionals is dedicated to delivering excellence in every aspect of our services, from initial consultation to final delivery.

Customer-Centric Approach

We prioritize understanding your unique needs and challenges, ensuring personalized services and solutions.

Innovative Solutions

Constantly exploring new technologies and methodologies to offer the most advanced and efficient manufacturing solutions.

Long-Term Partnerships

We strive to build lasting relationships with our clients, based on trust, reliability, and mutual success.